Solar Masonry Unit – Customization Options

There were several customization options I wanted to explore this week. It was important to first understand the needs and wants of the product users. In order to do so, it was also important to simplify and understand the product’s basic function(s):

1. Harness/Store Solar Energy

2. Stackable, Modular, Building Wall Unit

As a solar energy collector, the most important component is the solar cell. As a vertical surface on the face of the unit, the cell’s efficiency drops significantly when compared to a tilted cell at a specific angle. Additionally, the optimal angle of this tilt varies by location and climate. The tilt of the cell would want to be a customized and adjustable component for the user.

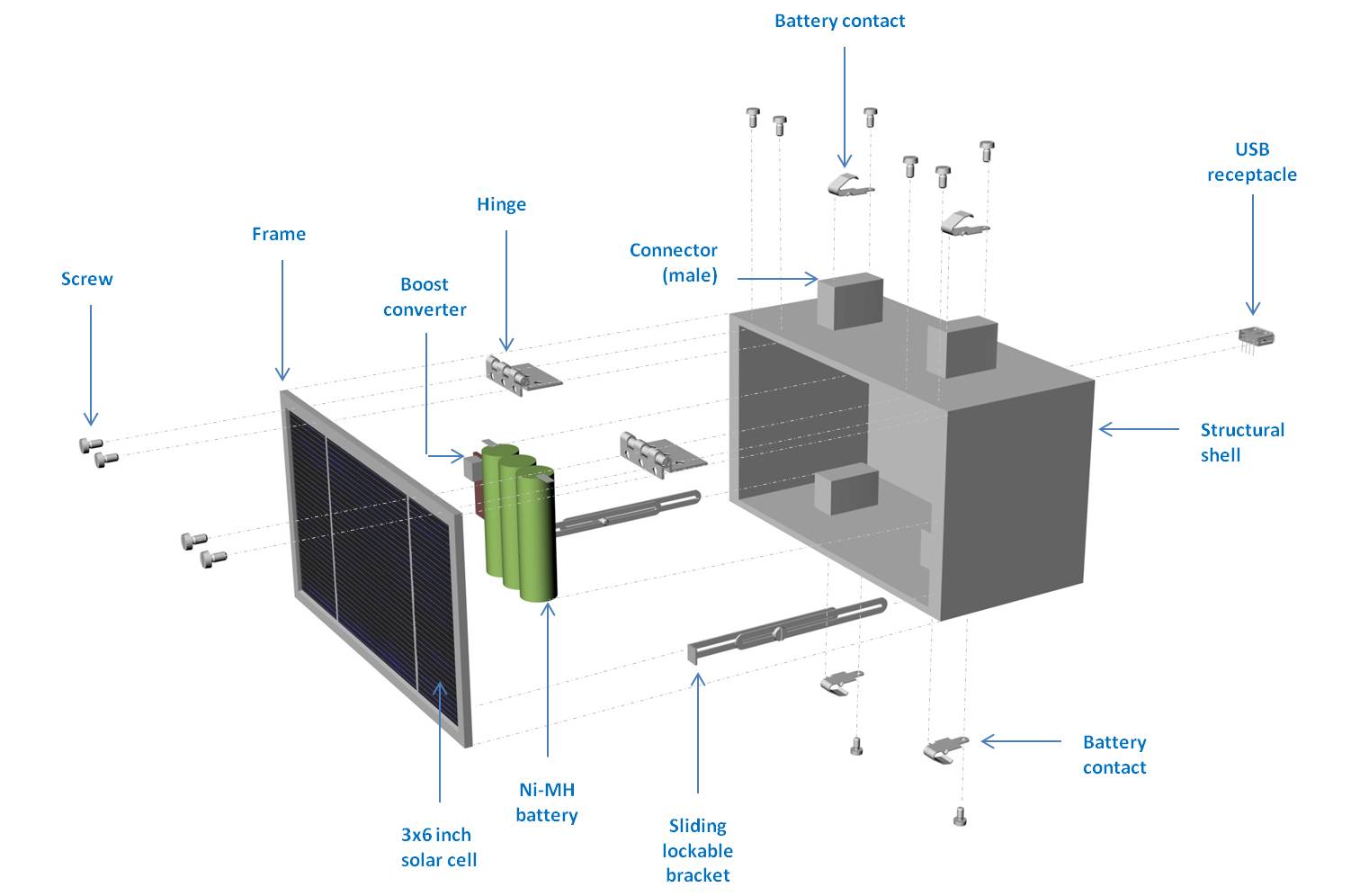

Each user would also want control over which type of cell is used on the product. Cells come in different colors and different technologies (mono-crystalline, poly-crystalline, thin-film, and organic). A frame that easily snaps or screws apart to accept different types of cells would also be desirable to the user.

As a modular building wall unit, the most important component is the structural frame. More specifically, end users would want control over the dimensions of the frame.

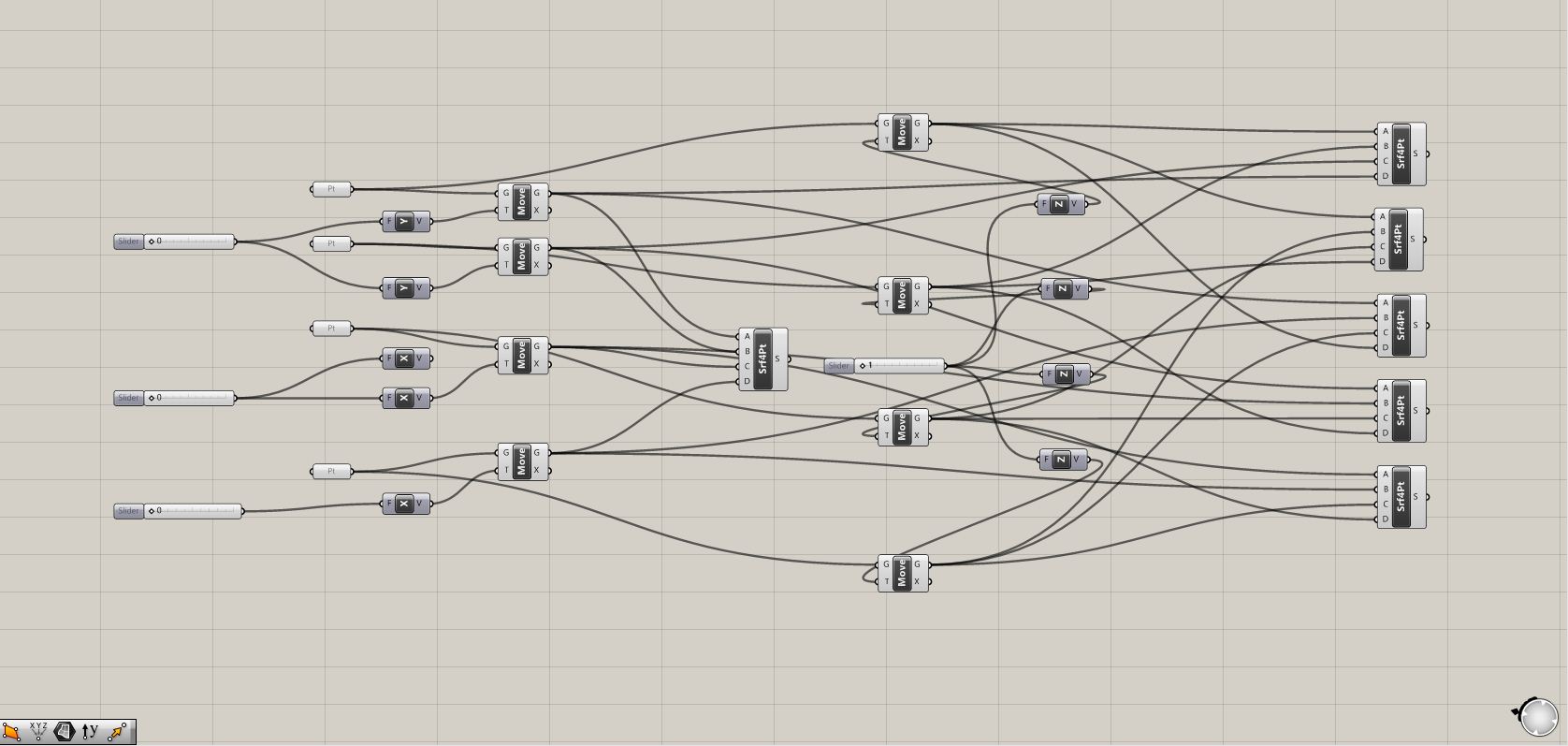

In order to test the customizable components of these two functions of the unit, I developed a parametric model in Grasshopper with the notion that the users could have control of the product during the production process. After production, the tilt of the face and the overall dimensions would be fixed according to a user’s preference.

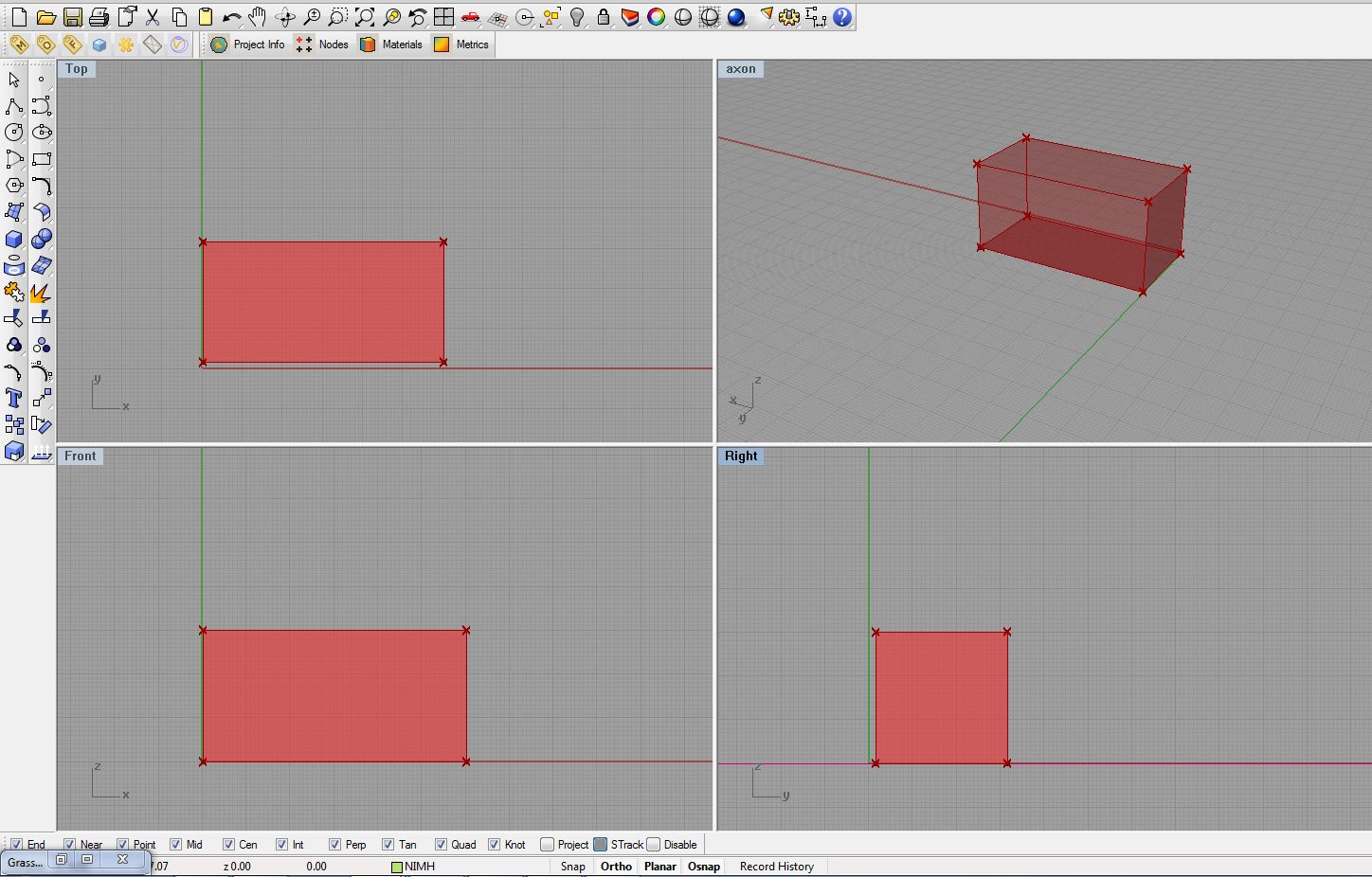

The set dimensions of the base shape are 6 inches x 3 inches x 3.5 inches. These initial dimensions are constrained by the size of a standard 6 inch x 3 inch solar cell. Users would have control over two aspects of this initial shape – the tilt angle of the face, and the overall proportions of the height (they can increase the height by two each time to allow for additional rows of solar cells above). The image below shows the initial, base shape.

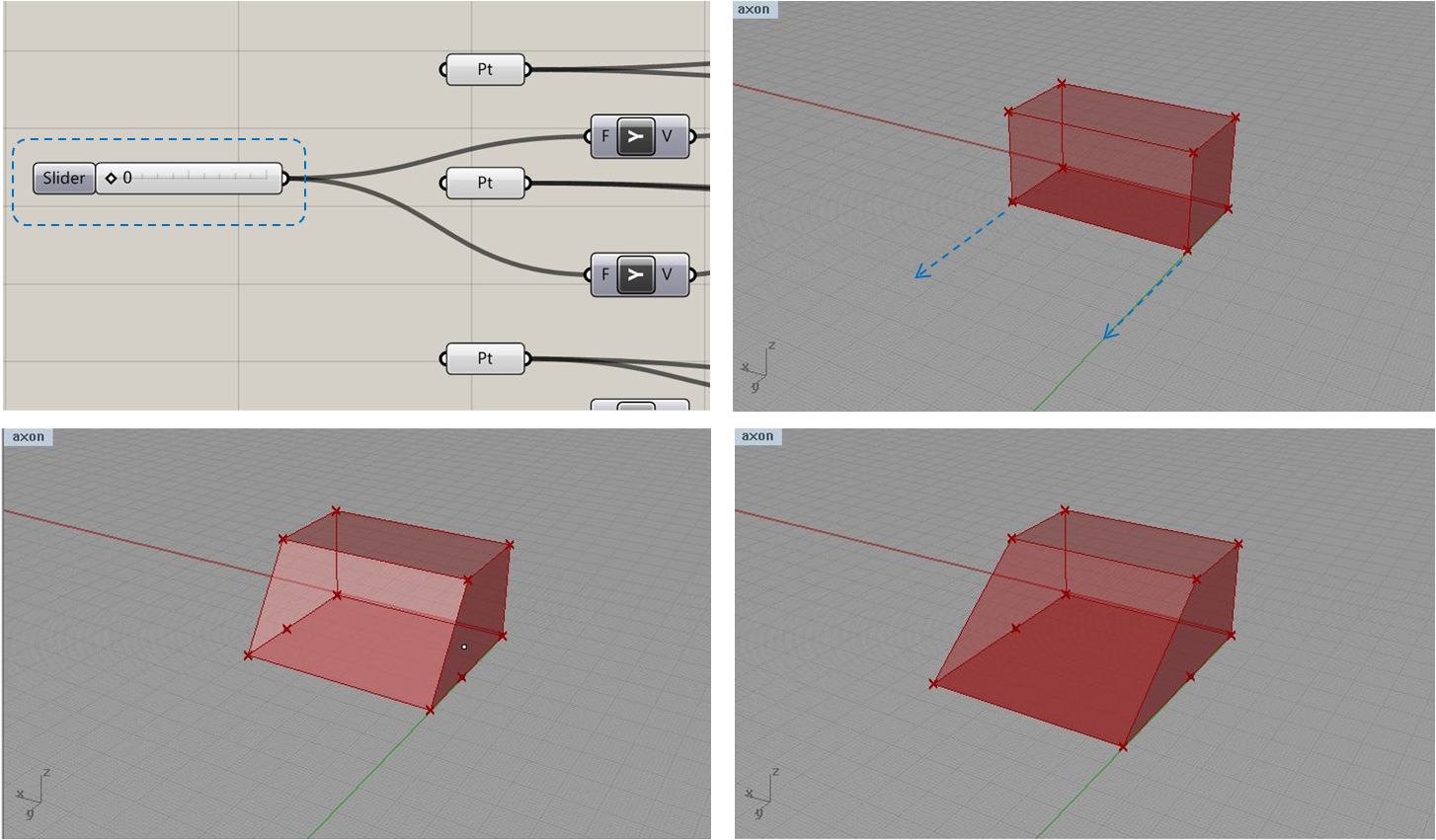

A slider allows the user to adjust the tilt angle and length of the face. The length doubles incrementally to allow the correct proportions of a second row of solar cells.

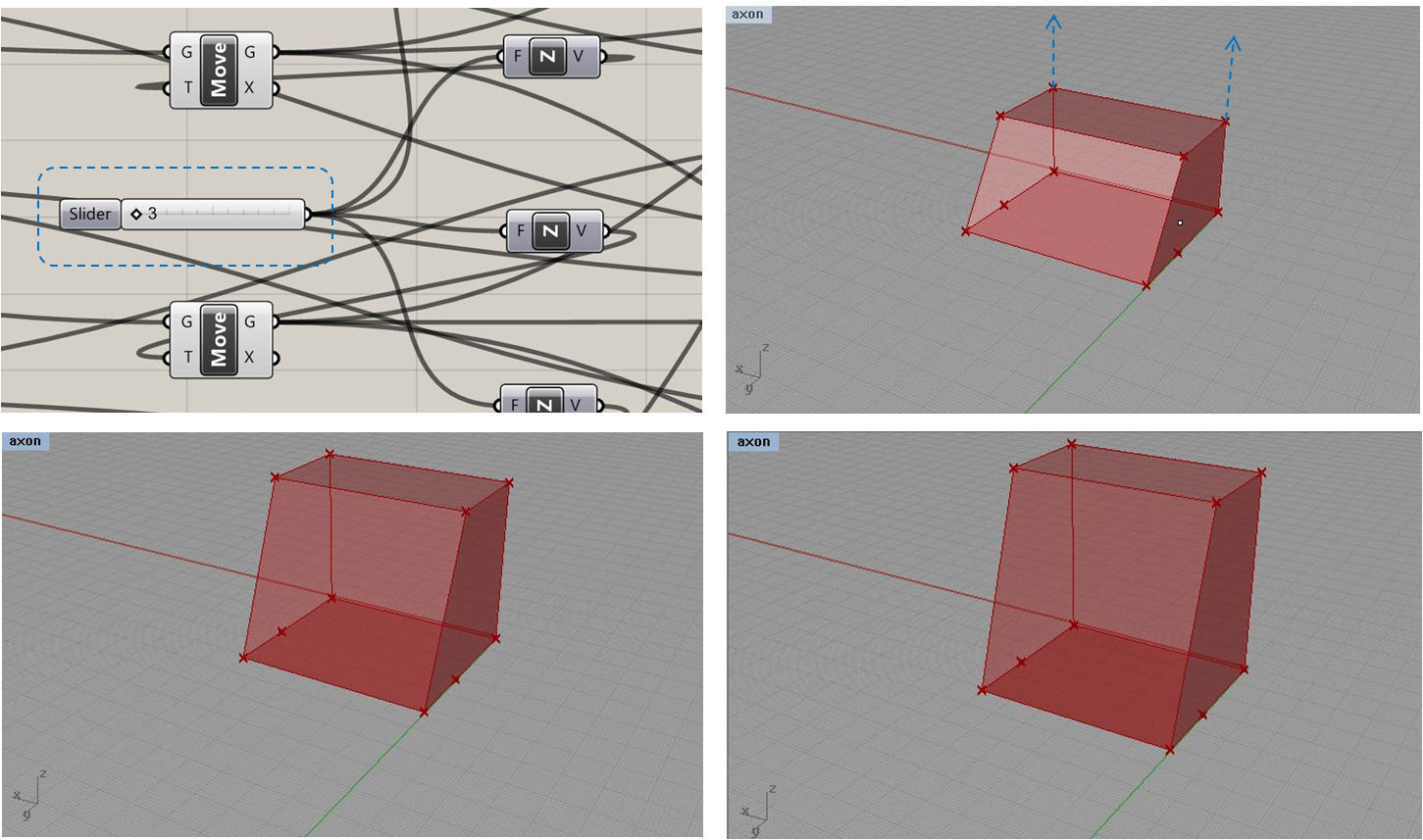

A second slider allows the user to specify a desired height for the unit.

I also wanted to explore ways in which the product could be customized and adjusted after production. The user would receive the product and have the ability to customize certain components using some type of mechanism. For this after-production customization, I focused on the tilt angle of the solar cell, and a disassemblable frame.

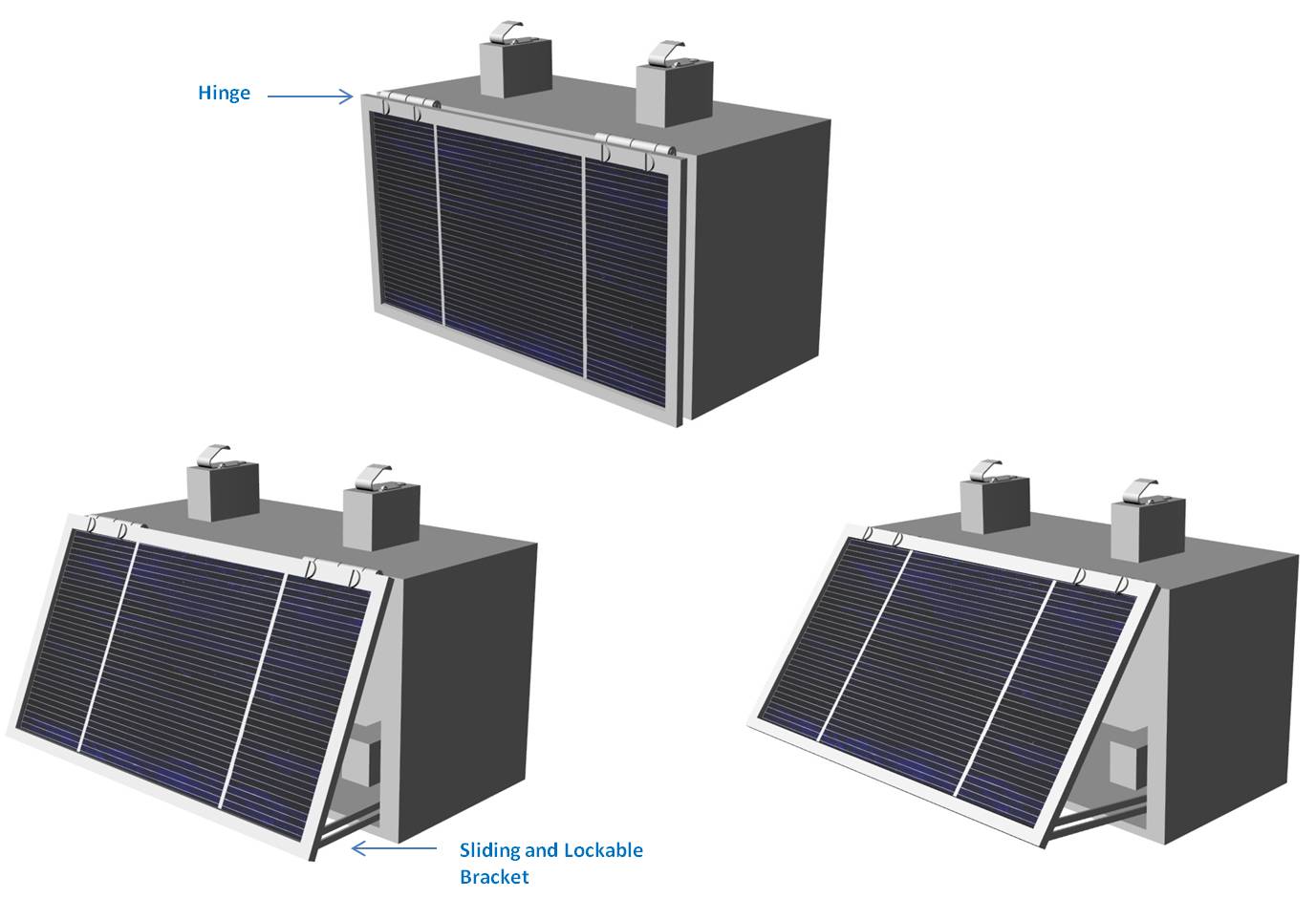

Using a simple hinge and a bracket that can slide and lock, the face of the unit can be completely adjustable.

There are several problems associated with the hinge and sliding bracket concept. When the solar cell is swung open to a desired tilt angle, the inner body of the unit is exposed. Since this product will be utilized outside, the electrical components would be exposed to varying weather conditions. This is problematic for obvious reasons.

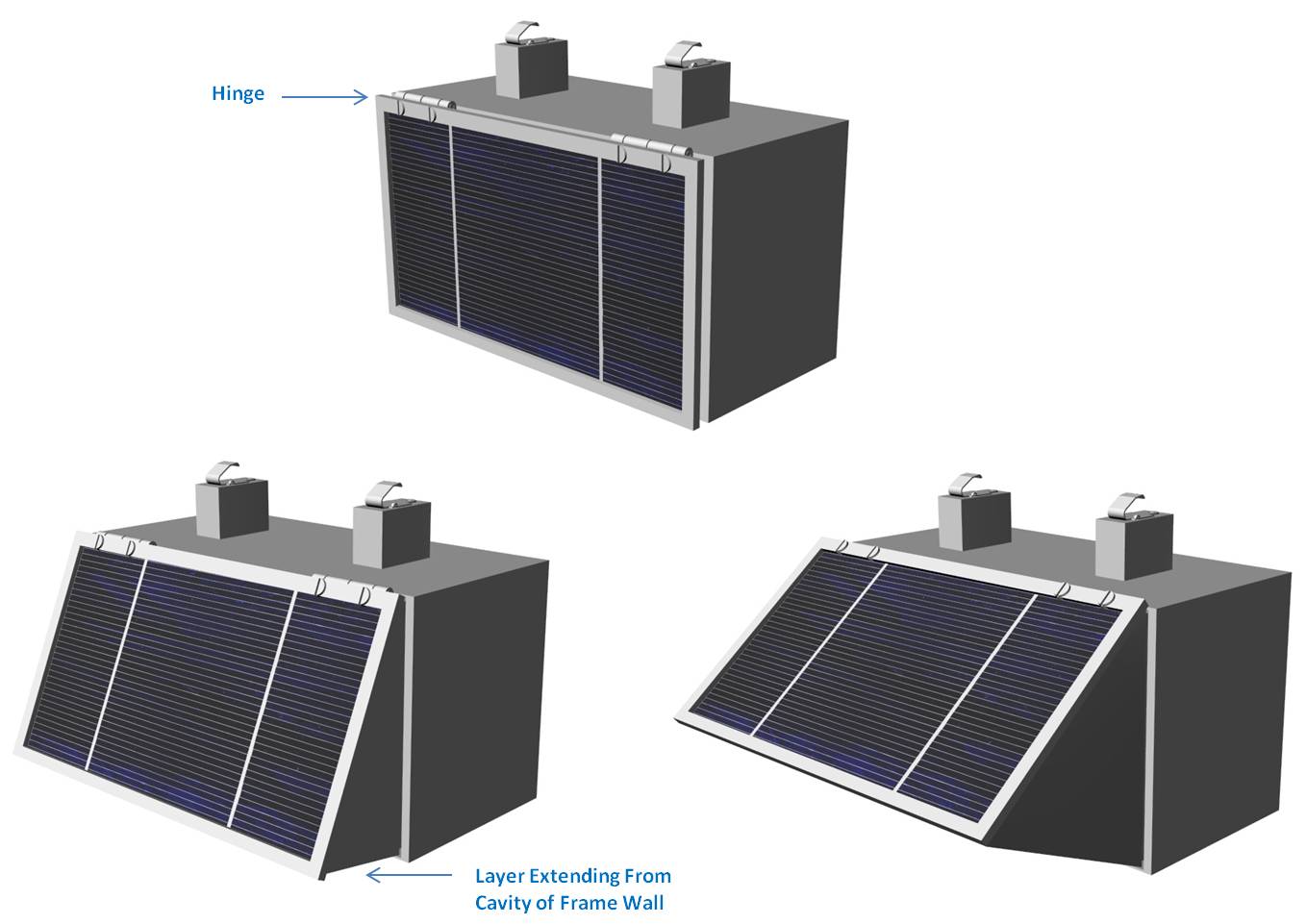

To resolve this issue, I explored a second concept. To insure protection for the electrical components, a internal layer of material extends from the frame when the cell is swung open.

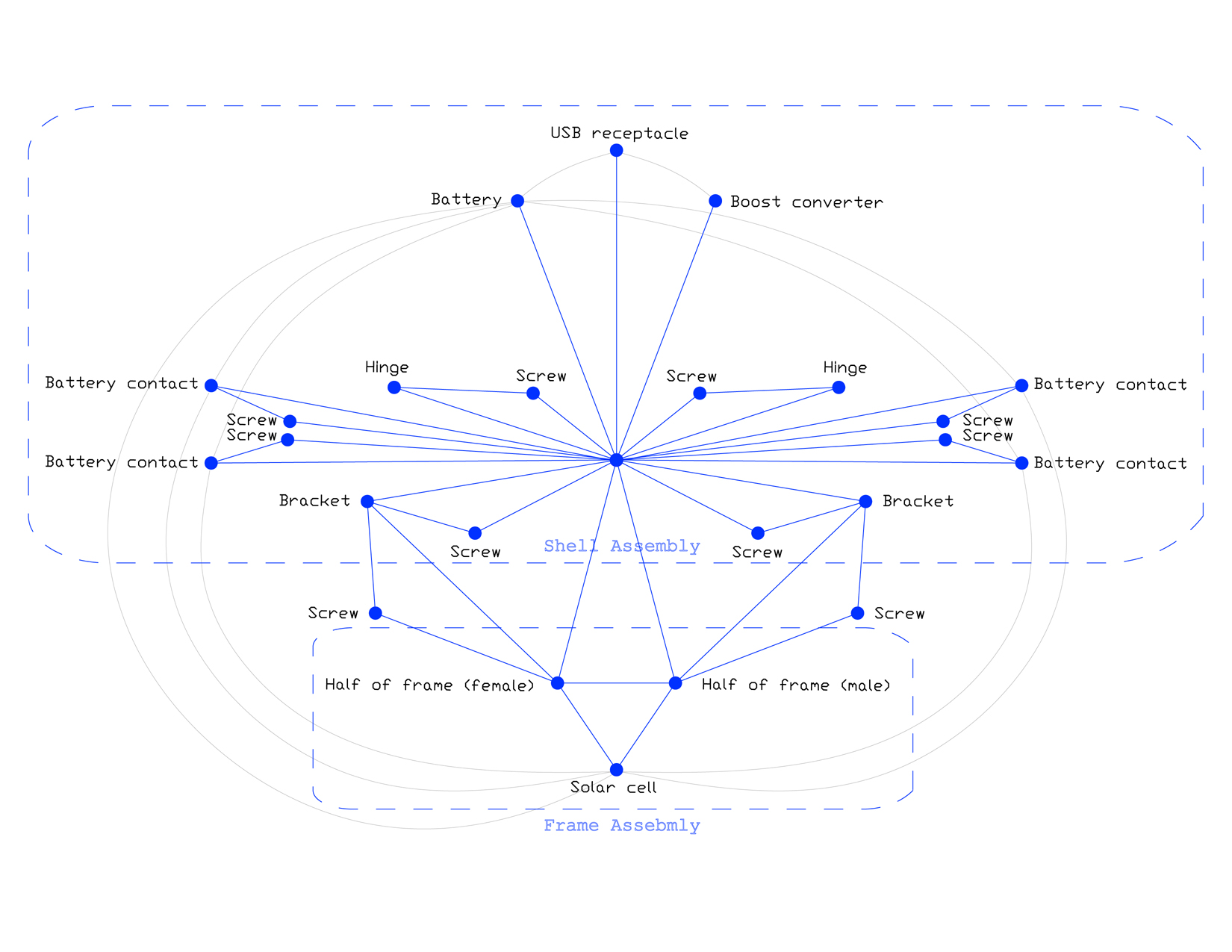

Liaison Graph

The grey lines represent soldered wire connections.