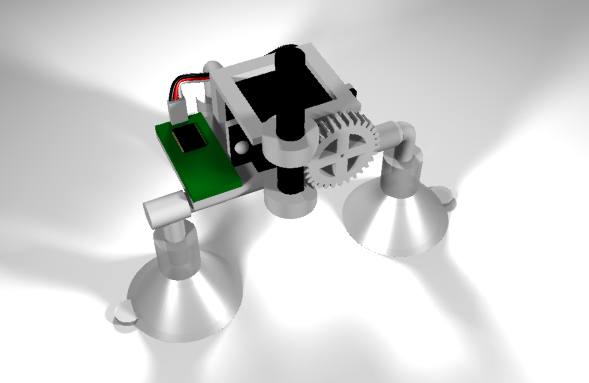

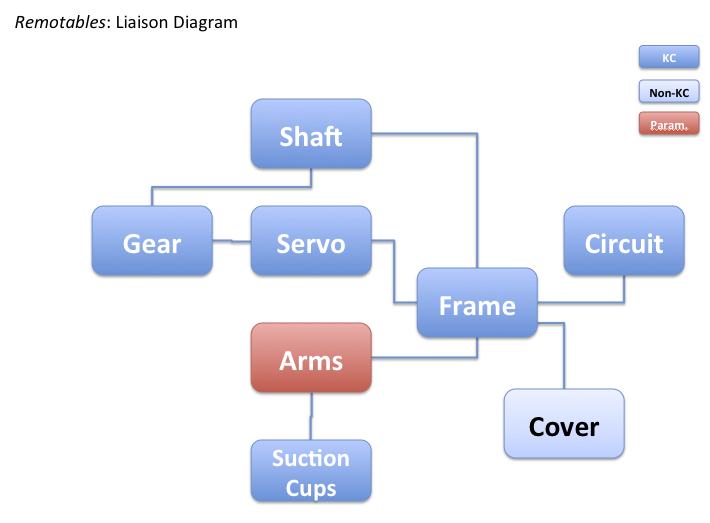

This exercise in fact brought me to think of an elegant solution for modularity of the Remotable.

The main problem I sought to solve is allowing the remotable to be attached to any surface and operate any button. This is a huge amount of flexibility. So actually allowing the user to control some of the dynamic parameters is a good thing for my product.

I decided to let the consumer control one of the most important factors – the latching mechanism. At this point I am pretty set on using suction cups for adhesion to surfaces, and recent experiments with silicone seem promising.

The consumer will basicaly get a “kit” of parts to control the form of the latching arms. Two parameters will be controllable – length and height. Length will have 3 pre-set sizes, height will have 2 sizes. Total the kit will have 3x3x2 = 18 parts. Maybe.

This will allow them to create versions of the Remotable with smaller or larger base to accommodate for different sizes of button surfaces.

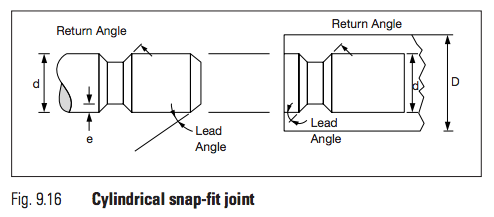

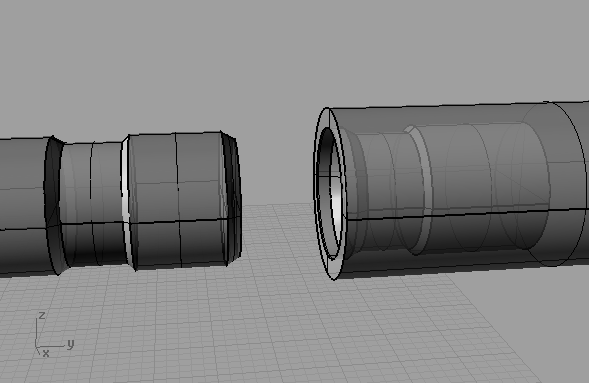

The parts fit on the frame sockets using a cylindrical snap-fit. I used this guide for inspiration for the fitting: http://plastics.dupont.com/plastics/pdflit/europe/design/L12565_9.pdf

My own fitting ended up like this:

The shaft is 5mm (d in Fig. 9.16), D is 6mm, lead angle is 30° and return angle is 45° (the guide recommends these) to allow a nice snap in but also an easy snap out. Regrading the groove (e in Fig. 9.16): I couldn’t see how a 0.18mm like the guide suggested will give any sort of hold, so I made it 0.25mm.