A Saga

So, at this point — I basically do not really have a working system. Rigging up the high-power LEDs to run off a portable, lower voltage source — as well as heat-sinking them. They dissipate a crazy amount of power, something like 700 mA * 6V [two LEDs] — or 4.2 Watts. That’s a lot of light from some little suckers, and they get bright.

Futures

- Figure out battery recharging. Even 2000 mA H won’t even last two hours, I think.

- Other options for boost voltage converters.

- Lens options. Reconfigurable? 3D-Printed? Why not?

- Hook up Rx/Tx FM transmitters–ordered from SparkFun

- Pressure sensors for handlebars

- Bandpass Filter for separating signals in the lights

- Time to have fun with the accelerometer? (now logging correcetly)

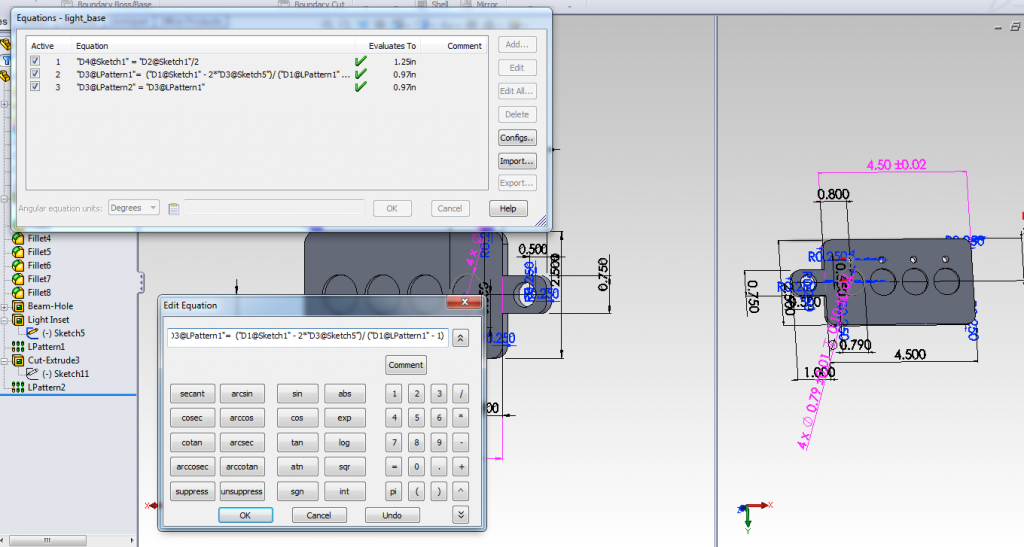

Parameterization

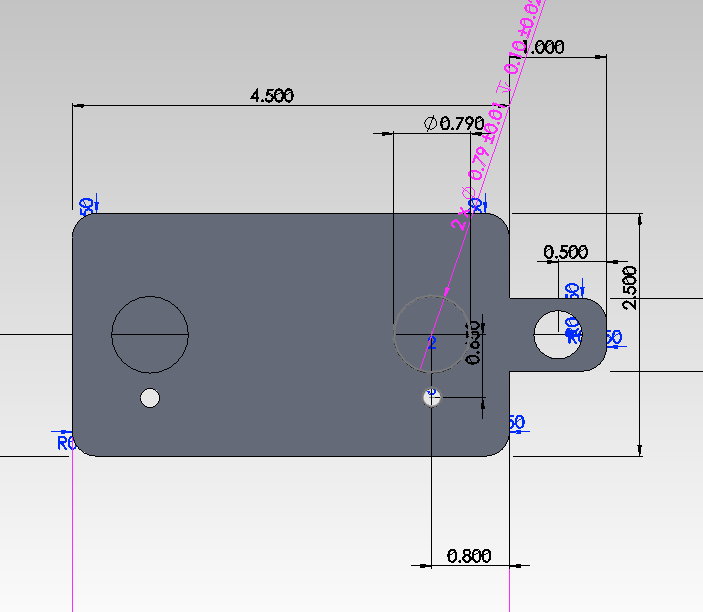

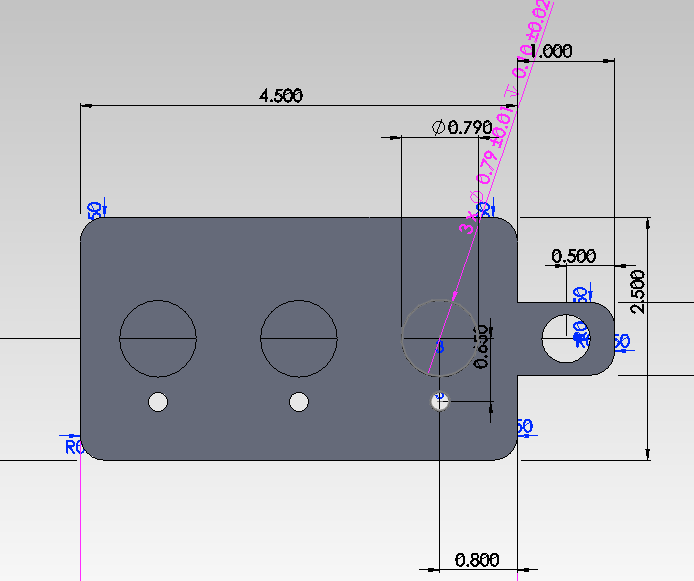

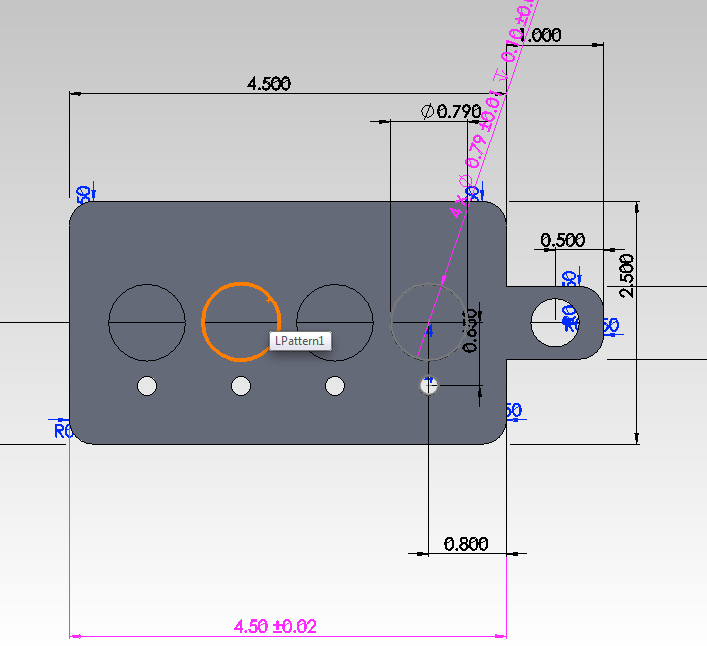

SolidWorks, unlike Rhino, is fully parametric, so in a certain sense, everything is configurable–though on a very micro scale. There isn’t a great interface for it, like Grasshopper–but you can just click on the various dimensions below to resize whatever you’d like.

To create more complex relationships between dimensions and qualities, you can configure equations to link together so that multiple variables change as you change other features. I’ve done a simple linking, by automatically spacing and position the seating-mounts for the LEDs for easy fabrication of various models. This would be customization on the fabrication end–and unless a user was familiar with the software package, it’d be a challenge to allow that customization. In some sense, this is just a way of streamlining a design tool–not ‘personalization’ in a true sense. On the other hand, lets say the qualities of your LEDs change — or you wish to quickly add a new variant — this makes it very easy.

Two lights. Evenly spaced.

Three lights. Oh, my!

Be still my beating heart, four lights!

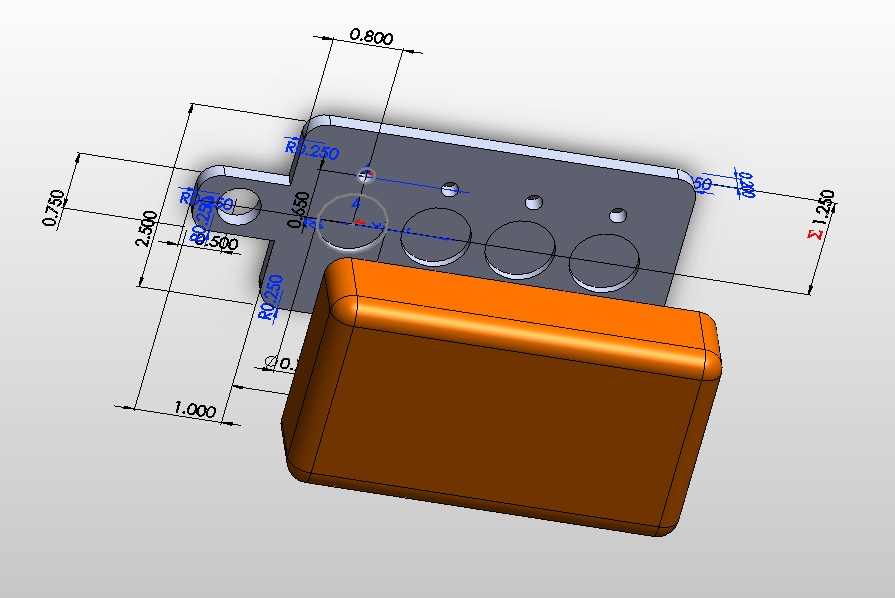

Here’s where it’s looking. I have yet to do any lens exploration, which is going to have to happen really, really soon.

Here’s a shot of the (awful) equation editor interface.

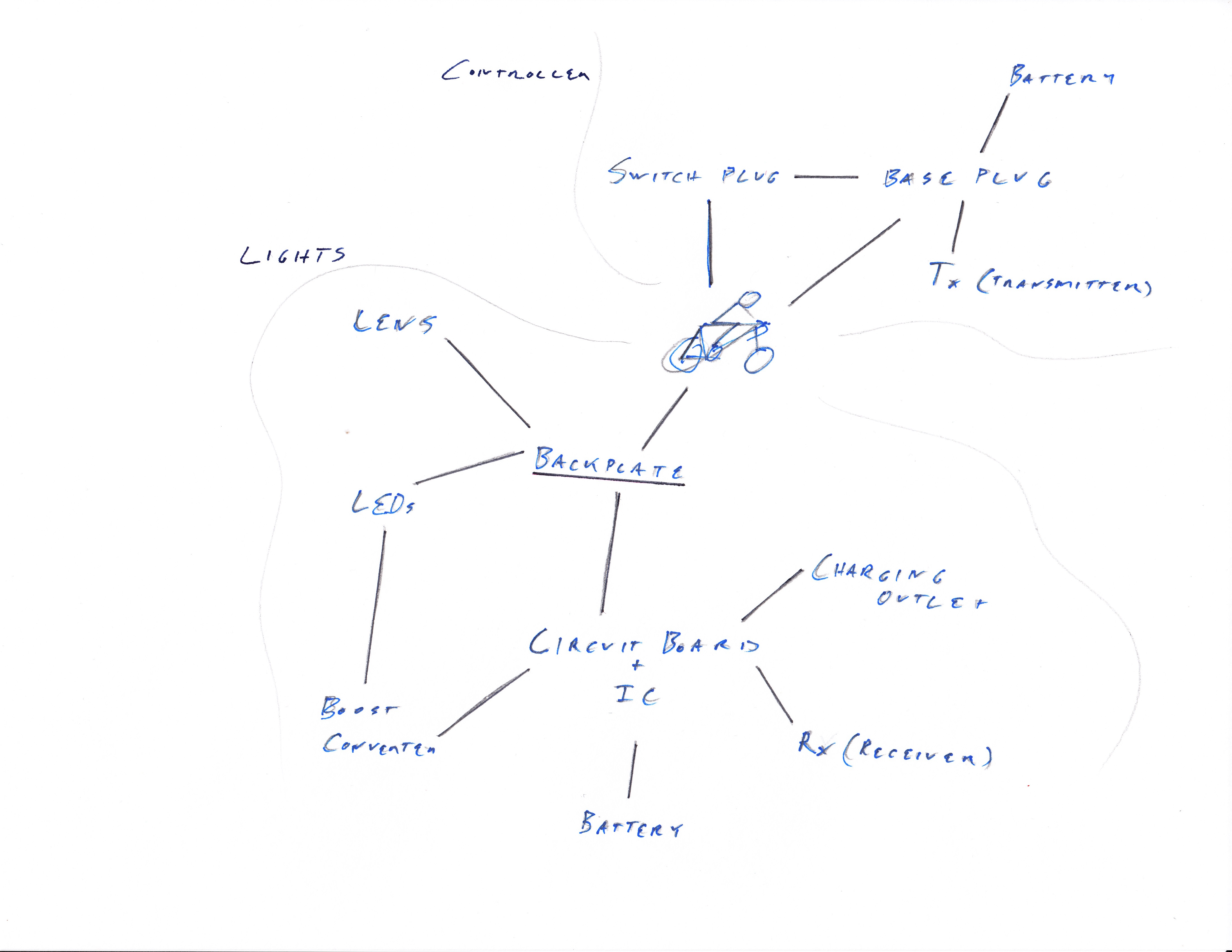

Assembly Architecture

The design is very integral–or at least, is split into two totally separate items, while each item is integral. I think there could be two ‘modules’, in considering the electronics and body separately, and then, somehow, snapping them together.

This shows the two sections. The bike, there, is in the middle. The circuit board itself, is the central node of one set of parts–and the blackplate (aluminum, for heat dissipation), the other. The board itself will be physically bonded (snap?) to the backplate–as will the LEDs, which will be attached with thermal paste.